- RESEARCH

- May 2023

- Bulletin

Cross Disciplinary Collaboration

DMS Team Uses Generative AI in Smart Manufacturing of Dental Crowns

The HKU Dental Materials Science research team: (from left) co-investigator postdoctoral fellow Dr Hao Ding, principal investigator Dr James Kit Hon Tsoi and PhD candidate Ms Yanning Chen.

The Faculty has made significant strides in the field of dental crown manufacturing. The Faculty’s team of leading researchers has devised a cutting-edge smart manufacturing technique that utilizes generative artificial intelligence (AI) in tandem with advanced dental manufacturing technology. This novel approach promises to revolutionize the way dental crowns are made, paving the way for more efficient and effective dental procedures.

The team, led by Dr James Tsoi, Associate Professor in Dental Materials Science, collaborated with colleagues from HKU Faculty of Engineering’s Department of Computer Science to take a big leap forward for the next-generation AI-designed dental prosthesis production workflow.

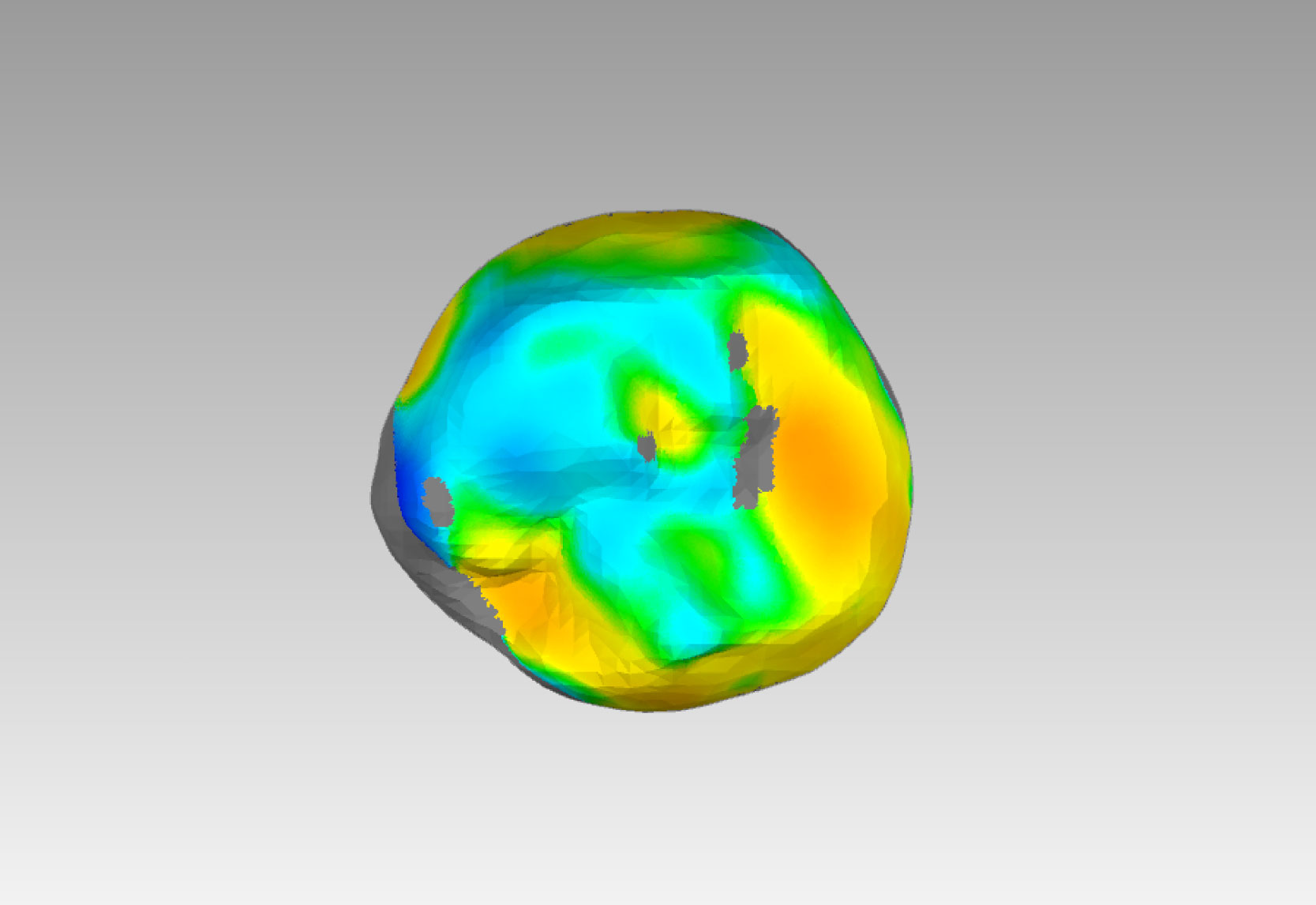

Researchers make use of generative AI to design personalised dental crowns.

The research team has devised a highly sophisticated generative AI algorithm that employs a true three-dimensional (3D) deep learning approach to create dental crowns that are personalised and highly accurate. These crowns closely mimic the morphology of natural teeth and are made from materials that match the biomechanics of natural teeth. Through biomechanical finite element analysis, the team has demonstrated that crowns designed using this AI algorithm and made from lithium silicate can come very close to achieving the expected lifespan of natural teeth. On the other hand, the two existing methods of designing dental crowns often result in crowns that are either too large or too thin, and they fall short of matching the same lifespan as natural teeth.

The results of this ground-breaking research have been published in the esteemed academic journal Dental Materials, in an article titled ‘Morphology and mechanical performance of dental crown designed by 3D-DCGAN’. Currently, the Computer-Aided Design and Manufacturing (CAD/CAM) digital workflow has significantly improved dentistry, but it still presents its fair of challenges. From the design to the manufacture of dental prostheses, the process remains labour-intensive and time-consuming. Additionally, the 3D printing and milling processes generate health and environmental hazards. The software currently used in this process relies on a ‘tooth library’ that contains predefined crown templates to assist in generating prosthetic designs and further adjustments by the operator are still needed to meet individual conditions.

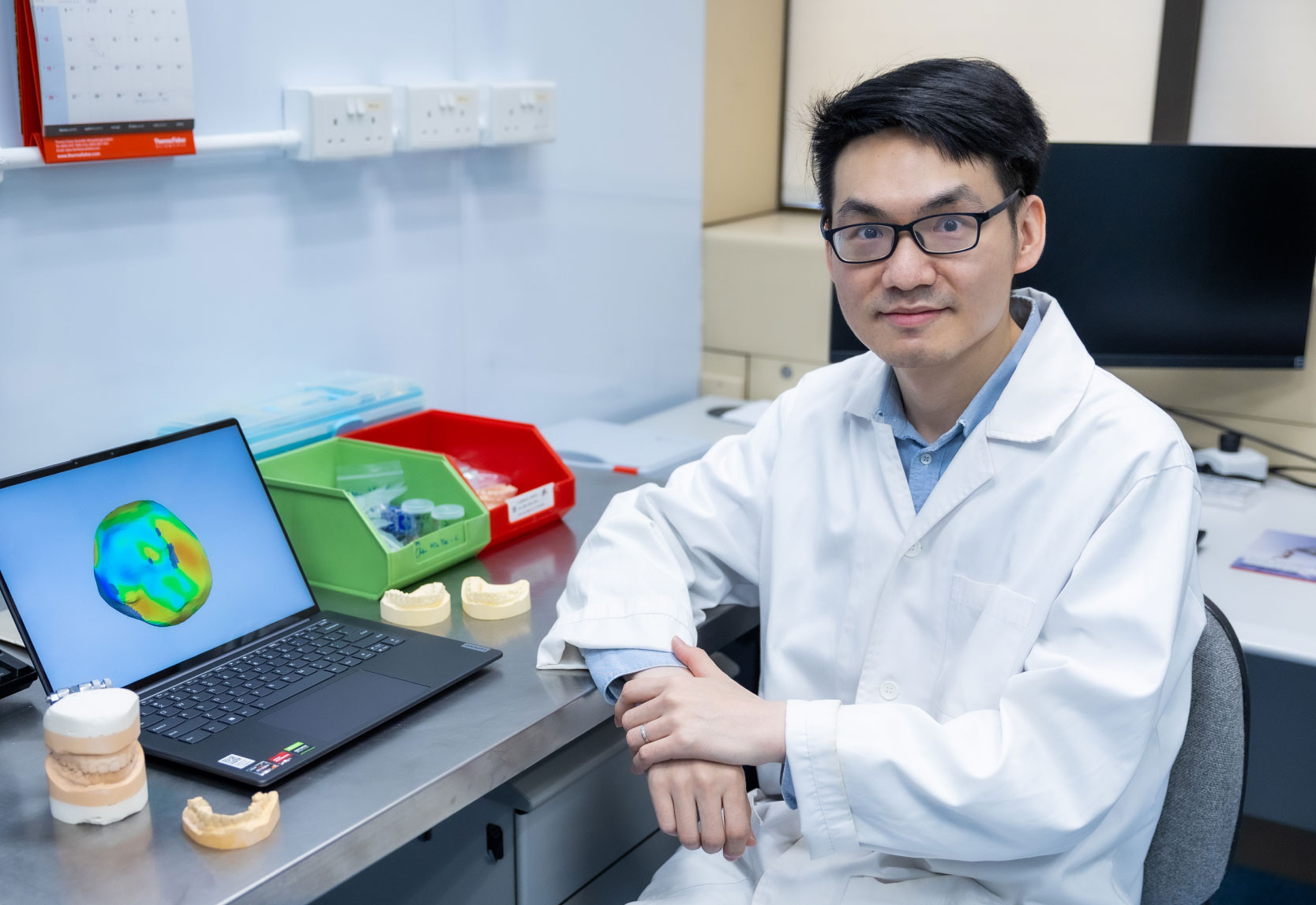

Project co-investigator Dr Hao Ding and the design of a personalised tooth crown using generative AI.

The revolutionary smart manufacturing method developed by the research team presents a solution to the challenge posed by the conventional approach to designing personalised dental crowns. “We used a 3D-DCGAN (3D-Deep Convolutional Generative Adversarial Network) approach to ‘teach’ the AI algorithm ‘good’ designs by feeding it with over 600 cases of natural and healthy dentition. The algorithm improves the quality of the design through internal competition between a generator and a discriminator,” explained Dr Hao Ding, a co-investigator on the project.

“During the training process, the algorithm learned natural tooth morphological features, enabling it to design dental crowns that are comparable to a natural tooth both morphologically and functionally.” Dr Ding added.

We used a 3D-DCGAN approach to ‘teach’ the AI algorithm ‘good’ designs by feeding it with over 600 cases of natural and healthy dentition. The algorithm improves the quality of the design through internal competition between a generator and a discriminator.

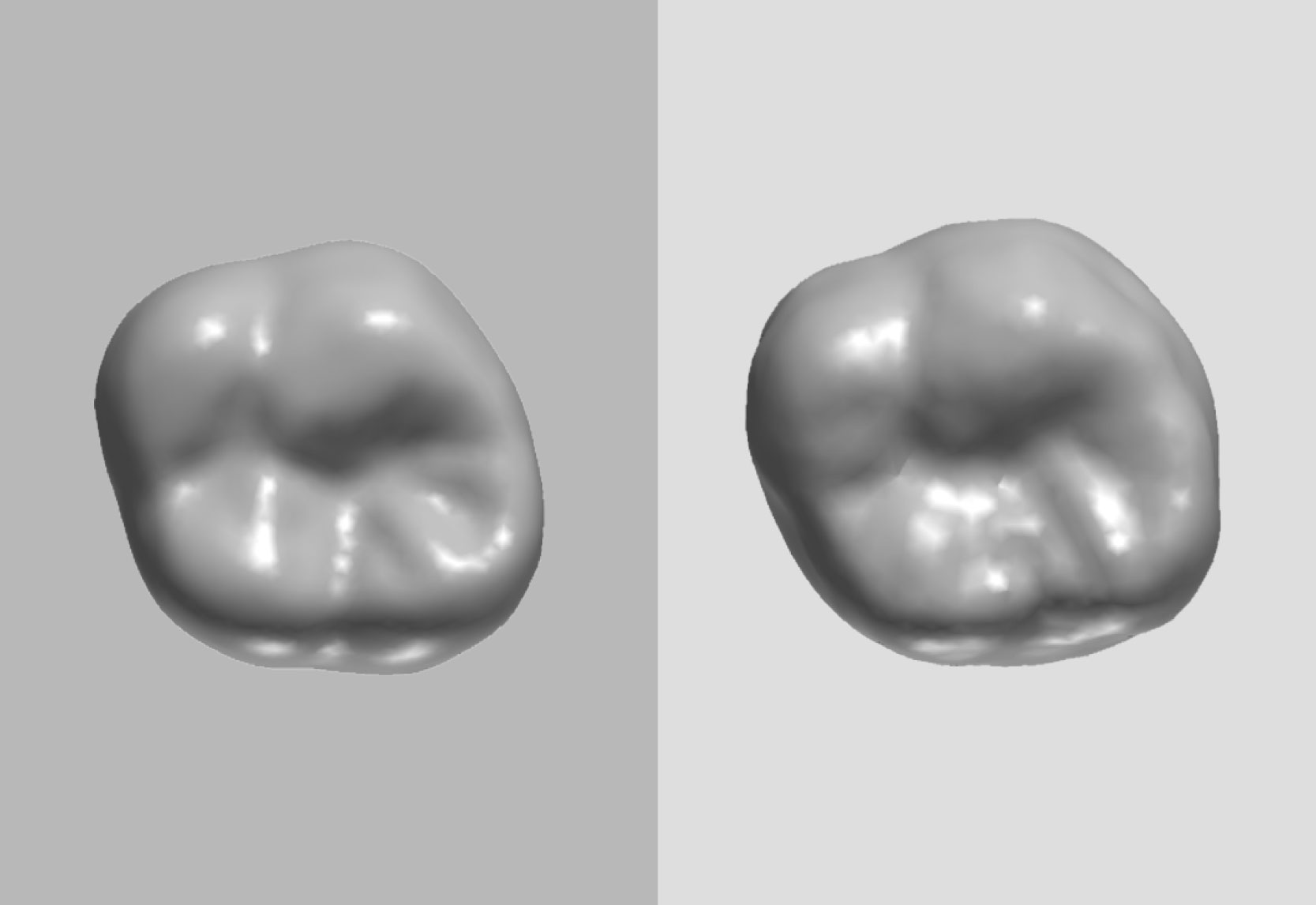

The 3D-DCGAN AI-designed crowns were compared with natural teeth and with two other conventional CAD methods of crown design. The findings revealed that the generative AI-designed crowns had the lowest 3D discrepancy, the closest cusp angle (morphological feature), and similar occlusal contacts (functional feature) when compared to natural teeth.

“This demonstrates that 3D-DCGAN could be utilised to design personalised dental crowns with high accuracy that can not only mimic both the morphology and biomechanics of natural teeth but also operate without any additional human fine-tuning, thus saving additional costs in the production process,” said principal investigator Dr James Tsoi. “Many AI approaches design a ‘look alike’ product, but I believe this is the first project that functionalises data-driven AI into real dental applications. We hope this smart manufacturing technology will serve as a stepping-stone for driving Industry 4.0 in dentistry, which is vital to meet the challenges of an ageing society and lack of dental personnel in Hong Kong.” He added.

The AI generated tooth crown closely mimics the morphology of natural tooth.

Dr Tsoi said the breakthrough marks an important step towards leveraging the dental industry in the Greater Bay Area, which sees an annual USD3.3 billion revenue for producing 25-30% dental prosthesis globally. It also aligns with the National 14th Five-year plan in developing new forms of industrialisation and informatisation, viz. smart intelligent manufacturing.

Clinical trials for using this generative AI for dental crowns are underway. The team is also exploring the applicability of this tool in other dental prostheses, such as bridges and dentures.

The study was supported by the General Research Fund (GRF), the Innovation and Technology Fund Mainland-Hong Kong Joint Funding Scheme (ITF-MHKJFS), and the Health and Medical Research Fund (HMRF). Its preliminary results were presented by Dr Hao Ding at the 35th Annual Scientific Meeting of the International Association of Dental Research (IADR) Southeast Asia (SEA). The study was awarded the leading IADR-SEA Research Category Award (Dental Materials and Biomaterials Category) in 2021.

Natural tooth (left) compared with tooth tailored by generative AI (right).

- Faculty of Dentistry, The University of Hong Kong

- Principal Investigator

- Dr James Tsoi, Associate Professor in Dental Materials Science

- Co-Investigators

- Dr Hao Ding, Postdoctoral Fellow in Dental Materials Science

- Ms Yanning Chen, PhD student in Dental Materials Science

- Professor Jukka Pekka Matinlinna, Honorary Professor in Dental Materials Science

- Dr Edmond Ho Nang Pow, Clinical Associate Professor in Prosthodontics

- Professor Michael Francis Burrow, Clinical Professor in Prosthodontics

- Faculty of Engineering, The University of Hong Kong

- Co-Investigators

- Dr Zhiming Cui, PhD graduate at the Department of Computer Science

- Professor Wenping Wang, Emeritus Professor at the Department of Computer Science

- Drexel University

- Co-Investigator

- Mr Ebrahim Maghami, PhD Candidate at Department of Mechanical Engineering and Mechanics

- University of Minnesota Twin Cities

- Co-Investigator

- Professor Alex Siu Lun Fok, Professor at Minnesota Dental Research Center for Biomaterials and Biomechanics